In the world of PCB cleaning, oftentimes up and coming companies rely on manual cleaning due to the cost constraints associated with cleaning equipment.

However, there are drawbacks to manual cleaning. The Human factor could result in inconsistent PCB cleaning from board to board. Manual cleaning exposes employees directly to solvent fumes. Because the solvents are used once and then disposed of (one and done), they are used in relatively large volumes per unit cleaned. Most solvents also contain VOCs that are restricted/limited use substances in many air quality districts.

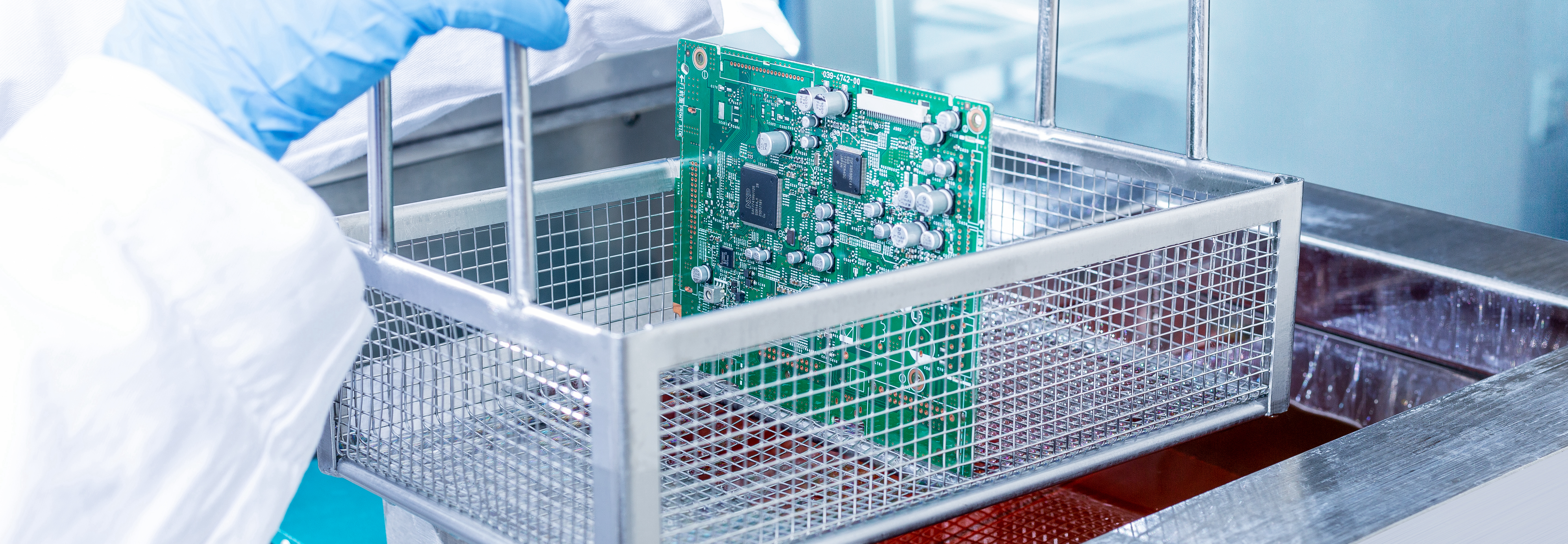

When traditional spray-in-air equipment-based cleaning is deemed too expensive, immersion ultrasonic cleaning using water-based chemistries can be less expensive in the long run, even when compared to manual cleaning.

Unlike manual processes, ultrasonics clean densely populated PCBs including under low stand-off components and complex geometries with repeatable results. High quantities of PCB cleaning can be accomplished in a short time with very little labor. From an environmental perspective, low-VOC PCB cleaning chemistries can be used and reused (which is a good thing).

Unlike manual processes, ultrasonics clean densely populated PCBs including under low stand-off components and complex geometries with repeatable results. High quantities of PCB cleaning can be accomplished in a short time with very little labor. From an environmental perspective, low-VOC PCB cleaning chemistries can be used and reused (which is a good thing).

Most components on PCBs are compatible with ultrasonics. If there is any doubt, the components can be evaluated for compatibility using the IPC-TM-650, Method 2.6.9.1 Test to determine the sensitivity of electronics to ultrasonic energy. Furthermore, some components are only incompatible with specific ultrasonic frequencies. Using the correct ultrasonic frequency will resolve that issue.

So, will an ultrasonic tank bought from Amazon suffice? What are the must-have features of a high-quality ultrasonic tank? There are certainly several things to consider in your search.

Keep in mind that ultrasonic equipment should be of industrial quality. Light-duty ultrasonic tanks can undergo cavitational erosion, which will wear away the steel over the transducers. Eventually, the tank will develop pinholes that will leak into the transducers and destroy them. Look for thick gauge steel and not thin “catering-pan” metal.

Here are a few tips to keep in mind for a successful search…

-

- The supplier should offer tanks in various sizes so you can choose a size that fits your board size and throughput.

- The tank should have sweep ultrasonics. The variation in frequency inhibits dead spots from forming in the tank due to standing sound waves.

- The supplier should offer ultrasonics with multiple frequency options. Lower frequencies (40 kHz) are more aggressive and more likely to cause component damage. So for sensitive components, higher frequencies (72kHz, 132Khz) could be used. A tank with multiple frequency options could provide the flexibility to clean all types of PCBs.

- The tank should have heater settings that can go up to 80C. 50-60C is typical for most PCB cleaning applications.

- The tank should have a timer for ultrasonic cavitation.

- Larger volume tanks may require more ultrasonic power (measured in Watts). The equipment technical information should show the power density (in Watts/liter), and the supplier should be able to explain why the tank was designed with that power density.

- Various fixturing accessories should be available.

Immersion ultrasonic PCB cleaning can be your first step toward a qualified repeatable cleaning process. If you think this may be a viable option to improve your PCB cleaning process, efficiency or gain better cleaning results, don’t go it alone. Industry partners and cleaning companies are ready to give you the information you need to make the best choice possible.

_1.png)