Maintenance cleaning is a pain, we know that. Just like cleaning your oven at home, it's the last thing on your mind and a low priority, but something that nags at you until you finally get around to it. It's the same with PCB manufacturing. Pallets, fixtures, condensation traps, and heat exchanges are just a few of the items that require maintenance cleaning to maintain efficiency and effectiveness. While some contract manufacturers have the financial means to allocate cleaning equipment for their maintenance cleaning needs, others are not so lucky and rely on manual cleaning.

In the wonderful world of SMT efficiency is key. So, if you are scrubbing, scraping and chiseling away for hours, what are your options? Build a cleaner!

It's not as difficult as you may think. Put on your DIY hat, find your local Home Depot or Lowes and let's get you started building your own Self-Designed Bubble Bath.

SELF-DESIGNED BUBBLE BATH

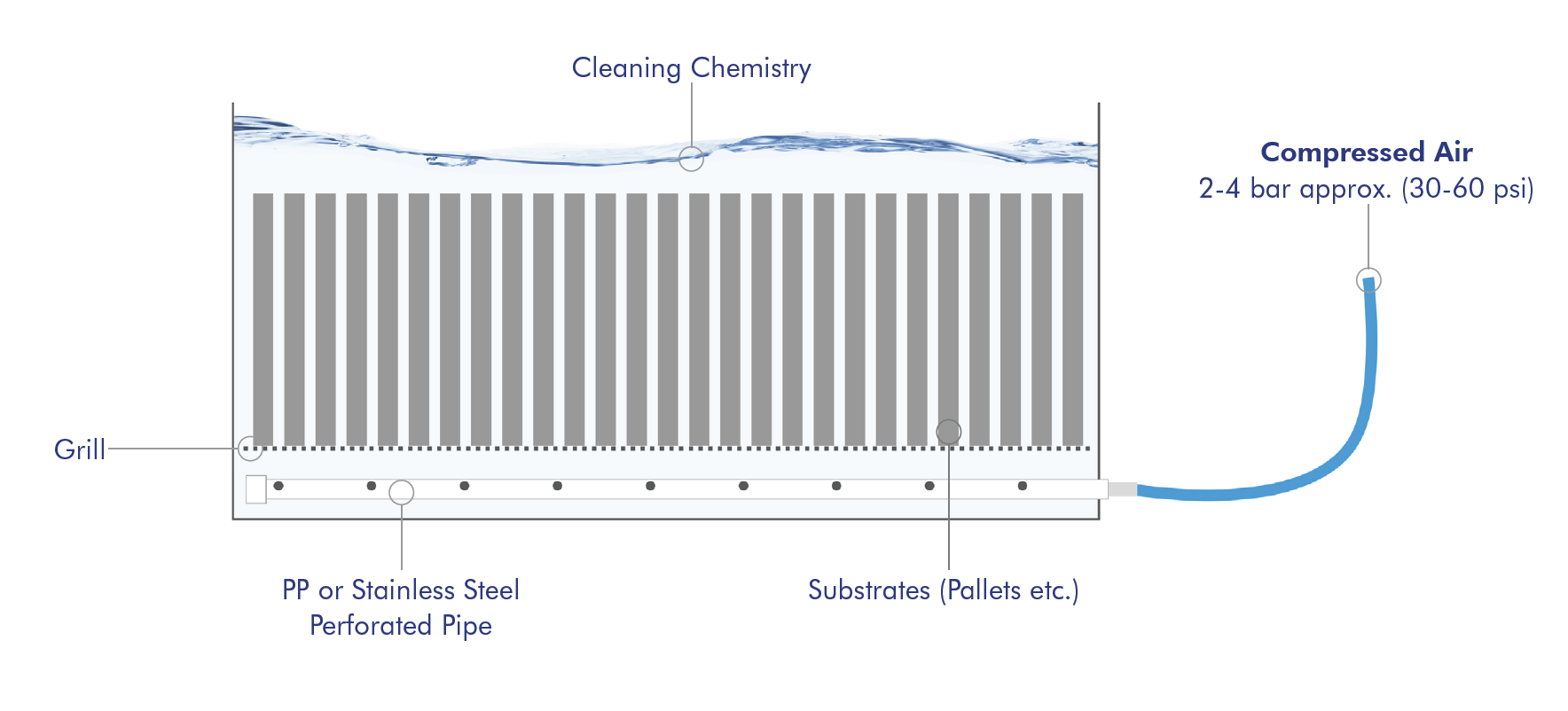

Depending on your cleanliness requirements, a simple, self-designed bubble bath may be an easy and efficient way to clean substrates (pallets etc.).

Our recommended process:

1. Determine the number of substrates to be cleaned at one time and build a PP or SS container (square or rectangular) large enough to accommodate your needs.

2. Install a PP or SS perforated pipe at the bottom of the tank that can be connected to low pressure (2-4 bar / 30-60 psi) compressed air to generate agitation within the bath.

3. Place the substrates in the tank vertically so that when fluxes are solubilized, they easily flow off the parts and settle at the bottom of the tank.

Additional Options

- Fixtures can be used to keep the substrates in vertical position.

- A heating coil can be installed to increase cleaning effectiveness.

_1.png)