In 2020, the high reliability electronics industry will see growth in the Aerospace and Defense, Medical, Telecommunications and the Automotive market segments. This growth is spurred on by the rapid evolution of advanced packaging which enables broader use of 5G technology (fifth generation of mobile broadband) and enabled numerous IoT (internet of things) opportunities within these industry verticals and in consumer electronic market segments.

We have seen technological advances in a variety of electronic package BTCs (Bottom Terminated Components) including:

-

- QFN (quad flat no lead)

- DFN (dual flat no lead)

- LGA (land grid array)

- MLF (micro lead-frame)

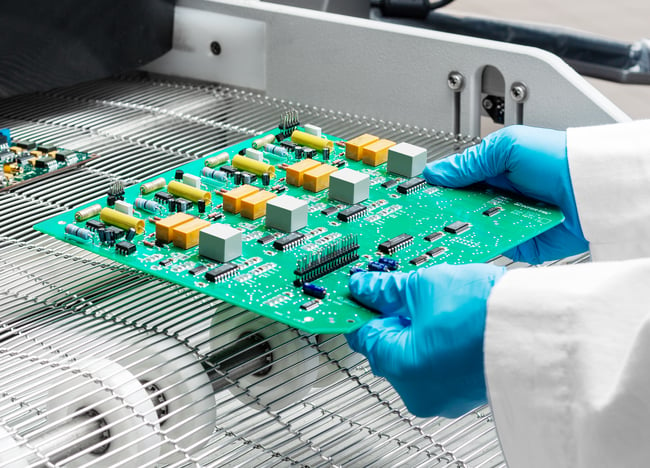

These types of packages are widely used in high reliability applications where risk tolerance is very low and failure is not an option for either components or assemblies. Given the critical function of these assemblies, coupled with exposure to harsh environments, corrosion and ionic residues present could lead to several types of assembly failures:

-

- Loss of transmission or signal integrity

- Electrochemical migration (dendritic growth)

To mitigate the risk of failure, ionic residues should be eliminated and conformal coating or conformal shielding applied to protect against the environment.

Materials used in building these complex electronic assemblies may include no-clean or rosin/resin-based solder paste and flux which are ionic in nature. Removing ionic residues left by thermal heat cycles through the manufacturing process increases reliability. Water-based cleaning processes using alkaline or pH Neutral cleaning agents with a good inhibition package ensures good material compatibility with sensitive components, metals and coatings. This cleaning process effectively washes the assemblies removing not only ionic contaminants, but all contaminants from over, between and underneath the assembly components.

Combining these electronics cleaning processes with cleanliness assessment techniques such as SIR (Surface Insulation Resistance) and IC (Ion Chromatography) analysis, can ensure that complex assemblies can stand up to high reliability performance standards.

For more in depth information visit our Technical Articles Section to learn more.

_1.png)