Would you wax your car without washing it first? Would you paint your patio deck without cleaning it beforehand? Perhaps you would. Perhaps you feel it would take too much time or cost too much. Perhaps you simply don’t feel it’s an important step. Let’s forgo the cleaning and get right to it. What would happen?

In the case of your car, it would be difficult for the wax to adhere to dust and dirt. The result is ineffective bonding to the paint and lack of shine. In the case of the patio, by skipping the cleaning you risk unsmooth surfaces and issues with paint adhesion because of oils or greases.

These are simple examples showing that because we did not clean, we increased our risk of a negative outcome. The same can be said for cleaning printed circuit boards (PCB) before conformal coating. Like the wax on your car or the paint and sealant on your patio, conformal coating protects the delicate components on your PCB from the environment around it.

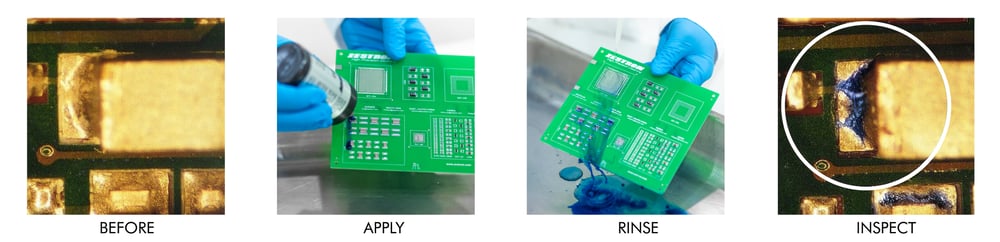

Cleaning PCBs before conformal coating removes potentially harmful and unknown contaminants from the board’s surface resulting in better adhesion of the conformal coating and thereby preventing delamination. Cleaning PCBs can ultimately prevent issues like leakage current, electrochemical migration and coating failures. From a production standpoint, it can help to decrease the cost of labor and time needed for the re-work of the boards.

Cleaning PCBs before conformal coating removes potentially harmful and unknown contaminants from the board’s surface resulting in better adhesion of the conformal coating and thereby preventing delamination. Cleaning PCBs can ultimately prevent issues like leakage current, electrochemical migration and coating failures. From a production standpoint, it can help to decrease the cost of labor and time needed for the re-work of the boards.

This brings me back to the examples of the car and patio deck. By not cleaning, we have introduced an element of risk of ineffective work or ultimately the risk of project failure. However, in the case of not cleaning before conformal coating, the risks can be much higher. The real-world risks associated with those failures can range from your computer’s mouse not working to medical or military devices failing. Depending on your level of risk tolerance, failures can be catastrophic.

From an additional cost perspective, you run the risk of increasing yours. In our example, the cost rises due to additional wax and paint needed for follow-up applications (at shorter intervals). In the world of printed circuit boards and high-reliability applications, you must consider the costs of field returns, warranty work, increased production cost (re-work) and the opportunity cost of lost production time due to failures.

Properly cleaning printed circuit boards before conformal coating is an important step in the production process and is something that should be strongly considered. So just like you would the next time you consider getting outside to wax your car or to tackle that patio project, take a moment to weigh the risks and costs associated with not doing thorough cleaning against the outcome you desire.

For more information and to take part in an in-depth discussion on this topic, please join ZESTRON Academy on April 23rd at 1:30pm EDT for a FREE webinar entitled Cleaning Before Conformal Coating.

_1.png)